HOSE FITTINGS

We supply a wide range of hose fittings including, cam & groove quick couplings, hose tails, swivel hose tails, non return valves, foot valves and strainers, ball valves, gate valves, breakaway couplings and Y-strainers.

We also supply a selection of nipples, including equal nipples, reducing nipples, reducing bushes, 90 degree equal elbows (FF) and (MM). Also Equal Tee nipples (FFF). We can supply most fittings in either brass, malleable iron and stainless steel.

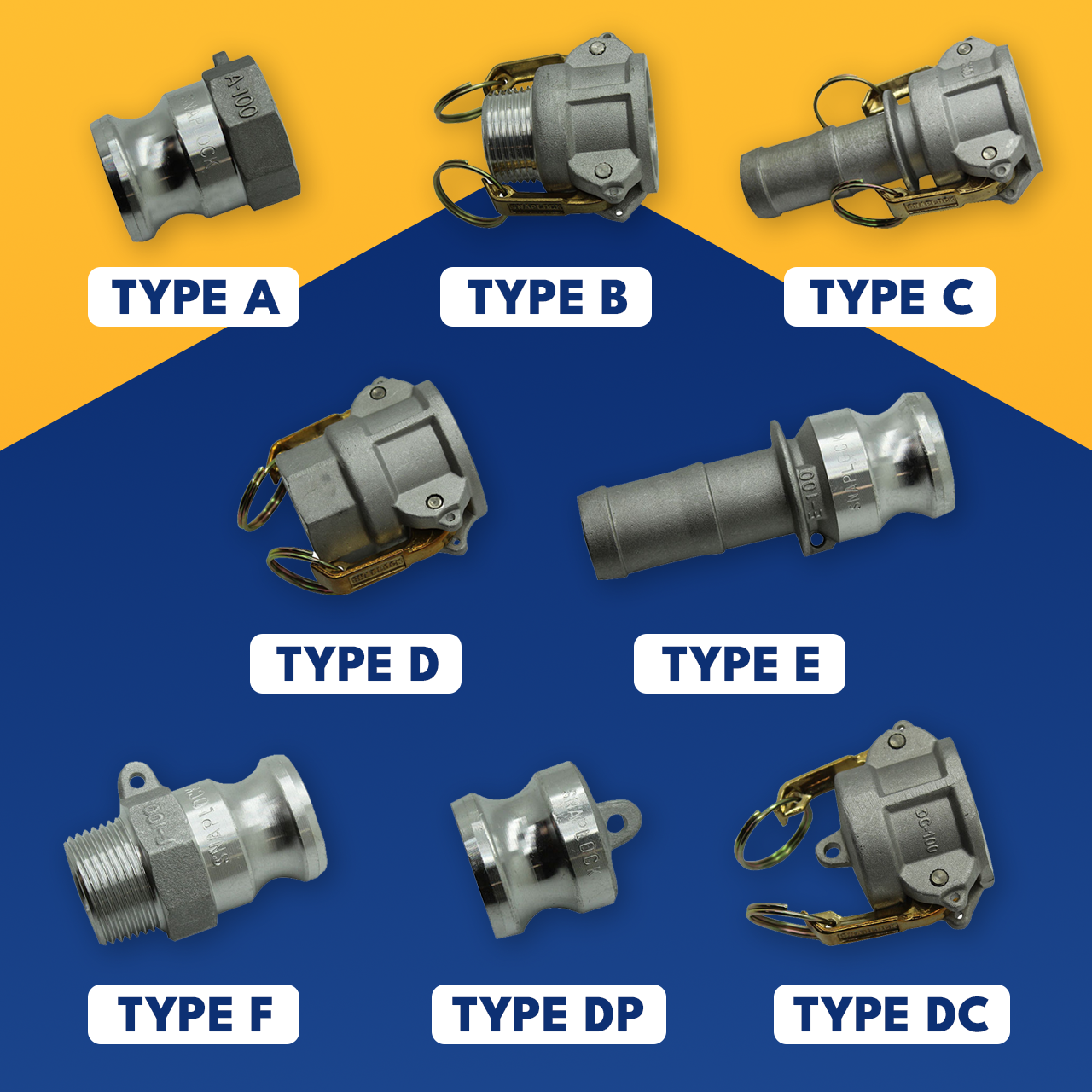

– CAM & GROOVE COUPLINGS –

Camlocks (also known as cam and groove couplings) enable you to quickly connect and disconnect your hose and pipework. They are designed to carry gases, powders, liquids, vapours and granules. Camlock couplings operate by opening the coupler arms and inserting the adaptor into the coupler. The arms are folded down into position to complete a tight join. A gasket is also supplied with the cam lock to ensure a tight seal when locked into position.

Camlocks are an ideal solution for hoses that are regularly taken on and off and connecting to different equipment. As part of the range, there are dust caps and dust plugs, which can be used when the hose is not in use and to prevent leaking whilst stowed.

Cam & Groove Couplings are available in both 1 inch and 2 inch. Made from high quality pressure cast aluminium.

– FIXED HOSE TAILS –

These tails are CNC machined in house in our workshop in aluminium to suit 1 inch and 3/4 inch hose. Should you require a large quantity please contact us for a lead time so we can plan your order on our machines. Available as straight connectors to fit same sized hose/nozzles or to act as reducer/enlargers to connect different sized hose/nozzles. Suitable for diesel and most standard fuels. Not suitable for use with AdBlue.

All BSPM threads are parallel with the exception of ‘1 BSPM Taper x 1 Tail’, which is suitable for use where it is not being fitted into a nozzle/swivel that has a seating washer. You will need to ensure you have the correct size jubilee clips to attach the hose tails to your hose.

– SWIVEL HOSE TAILS –

Swivel fittings are rotating adapters and connectors that are often made available in metal for better durability and strength. Important benefits of using swivels include. Extending hose life. Eliminating kinks in supply lines, reducing the frequency of the the hose getting twisted and tangled up after a hose has been in use. Reducing maintenance frequency and costs. They are usually available for different media & fluids in compatible materials and sizes. Below we are offering 1″ or 3/4″ in either Aluminium or Stainless Steel, usually used primarily for diesel, petrol or AdBlue.

Strong and reliable Swivel tails, for use with petroleum fuels do save on time on maintenance where a standard fixed tail will take all the force and remain rigidly in place whilst the hose is manoeuvred about potentially causing a weak joint and possibly leaks, whereas a hose with a swivel in place will allow the hose to rotate around freely while the hose is in use and being manoeuvred.

– GATE VALVES –

A gate valve is a control valve that either allows media to flow through unobstructed or stops the fluid flow. The main advantage of this type of valve is the straight-through unobstructed passageway, which induces minimal pressure loss over the valve. A gate valve is the most common valve for water supply & fuel supply systems. It represents a linear-motion isolation valve and has a function to stop or allow the flow. Gate valves got their name from the closure element sliding into the flow stream to provide shutoff and, therefore, acting like a gate to close off the flow of the valve to the onward pipeline. During use, these valves are kept either fully open or fully closed. The disc of the gate is completely removed when turned open, allowing contents to pass through oil gate valve.

BSP Female to Female ports, brass body and painted steel on/off handwheel.

– LEVER BALL VALVES –

These ball valves are isolation valves that allow you to quickly and easily reduce or turn off a fluid or gas supply. They’re used on steel pipe systems and usually have threaded ends for easy installation. When would you use this style valve ? Ball valves are smaller than gate valves, but they require more space for operation. A manual lever valve requires a lever that can turn 90° but a manual gate valve can operate with a small handwheel. Some ball valves are available with small form factor handle options, such as wing or round-style handles.

Lever action full bore valve, brass body, plated finish, manufactured and tested to BS EN 331 by a BS EN ISO 9001 registered company. Plated steel lever handle with yellow plastic coating.

Taper threads to ISO 7. For Natural Gas and LPG. These are available in all sizes for 1/4″, 1/2″, 1″ and 2″ sizes.

– NON RETURN VALVE & STRAINER –

These are essential for use where the pump requires an initial prime to get it working and you wish to maintain the prime thereafter without the fuel dropping back to the tank, therefore causing excess work for the pump the next time it is used. The pump is working its hardest when it has to be primed as it has to pull the fuel from the tank this is usually working against gravity so the motor and the rest of the parts are working to their fullest, if this can be avoided each time the pump is used then this will obviously extend the life of the parts and prevents breakdowns. It will also ensure that the next time the pump is used it is ready to dispense right away rather than having to re prime itself.

There is a separate strainer basket available for the 3/4″ and 1″ F-F NRVs – please add to cart separately if required. These Strainer Baskets are Male threaded to fit into the inlet of the Female threaded NRVs. The Strainer has a fine mesh to prevent large debris from being drawn from the bottom of the tank into the hose and then into the pump potentially causing damage.

– LEVER BALL VALVES –

A Y strainer’s purpose is to remove unwanted particles from steam, gas, or liquid using a straining element typically made of wire mesh. Using this mechanical process in pipelines helps to protect everything from pumps to steam traps. Y strainers are sometimes designed with “blow-off valves” to make the cleaning process easier.

Perhaps the largest benefit that comes from the y type strainer is its flexibility. It can be installed in a vertical or horizontal position, depending on the users’ preference. While this strainer type is already a cost-effective option, the size of y strainers can be reduced to save even more money. This also prevents using excess materials. Y strainers can be made of a variety of materials. The type of material you choose depends on the industry and application that is used. Any type of end that you might need is available as well. From socket to flanged, there is a y strainer out there with the end you need!

Send us a message.

If you need to contact us for more product information or to receive a quote, please don’t hesitate to get in touch.

Follow on Social

Opening Hours

Monday – Friday 8:30am to 5:30pm

Saturday – Closed

Sunday – Closed